一、Product Introduction:

High temperature resistant hydrochloric acid, high temperature sulfuric acid, high temperature mixed acid and strong acid high temperature medium

The manufacturing process of Germany advanced production, breakthrough limit the field of high temperature acid resistant pump, is the sole owner of synthetic graphite nano graphite manufacturing process through anti static pressure pump technology, to break the foreign monopoly and market subdivision technology is an alternative to avoid Lei, Hastelloy, ideal for titanium alloy and rare metal alloy materials.

Product overview:

THZWS graphite axial flow pump is our independent research and development of new design of high temperature resistance, acid resistance, corrosion resistance, abrasion resistance inside the axial flow pump, using graphite material, ideal material for high temperature resistant acid medium, which has excellent heat resistance, corrosion resistance, and has very good wear resistance and excellent impact resistance the performance, can adapt to the different working conditions of the pump, the pump which has the advantages of corrosion resistance and wear resistance, the use of a wide range, especially suitable for high solid content, high temperature corrosive medium strong acid (containing solid particles weight concentration is less than 10%, the solid particle diameter less than 1.0mm).

THZWS graphite axial flow pump

Product advantages:

1. THZWS graphite axial flow pump is our company according to the standard of GB/T13008 technology combined with the design of non metal pump manufacturing plate type graphite axial flow pump has the advantages of high temperature resistance, corrosion resistance, abrasion resistance, high mechanical strength, high efficiency and energy saving, in -30 to 180 DEG C in the harsh environment of long-term use can be assured.

2. pump body, impeller, cover, seal box, shaft sleeve, protective sleeve, throttle ring, impeller cover flow of the main material used impregnated graphite (carbon fiber, glass fiber, copper and other materials) for different working conditions selection.

3. pump shell graphite material, thickness 30mm-50mm, clamp design, metal support, limiting the full plastic pump shell heat graphite axial expansion and compression permanent deformation of axial compression, overcome the pump body deformation, shrinkage deformation leads to unstable mechanical properties the shortcomings of using the CFD computer fluid mechanics design of hydraulic components module design and molding, should be able to withstand the high speed and high pressure liquid erosion, and can withstand the effects of instantaneous thermal shock, has high anti cavitation ability, size precision, smooth flow, good interchangeability, effectively improve the operation stability of graphite axial flow pump.

4. impeller with integral graphite materials, module design and precision machining of CFD computer fluid mechanics design of hydraulic components, ensure the reliable transmission of torque, open structure, channel optimization design, high efficiency, low NPSHR value, to ensure the stability of the flow and lift pump;

5. pump seal for the container type, double end resistance to high temperature, corrosion resistance, wear-resistant machine seal, can transport containing particles, crystallization medium. Configurable API682 standard seal layout and flushing scheme;

5. machine sealing ring and static ring adopt high wear resistance and temperature resistant crystal silicon carbide material or HC276 alloy. It has high strength, good wear resistance, good self resistance and strong corrosion resistance. It can effectively guarantee the service life of the pump;

6. rear pull design, no disassembly of the pipe, easy maintenance;

7. structure: vertical, horizontal, direct drive, belt drive, hydraulic coupling, universal joint drive.

Scope of application: suitable for axial flow forced circulation pump: diaphragm caustic soda, phosphoric acid, vacuum salt, calcium lactate, alumina, calcium chloride, ammonium chloride, sodium chlorate, sugar, salt, papermaking, wastewater industries such as evaporation, concentration, cooling, in order to improve the production capacity of the equipment, increase the heat transfer coefficient of heat exchanger the use of forced circulation. It is especially suitable for high temperature hydrochloric acid, high temperature sulfuric acid, high temperature mixed acid and strong acid high temperature medium;

Performance range: design pressure: 1.6mpa;

Caliber: 250 ~ 1000mm;

Flow rate: 300 ~ 12000m3/h;

Lift: 3 ~ 5m

Power: 7.5 ~ 250kw;

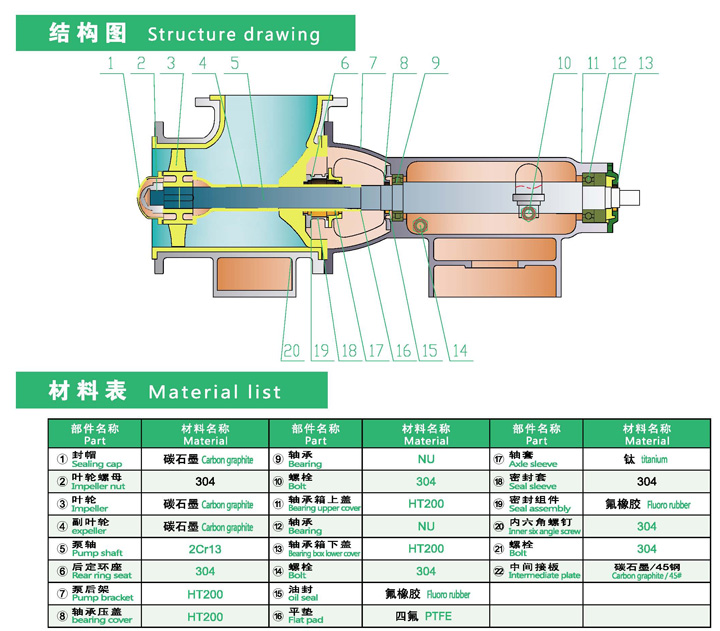

二、Structure drawing:

PRE:暂无!