| Meaning | THZF80-65-160 |

| T | Code of enterprise |

| H | Standardlized chemical pump |

| Z | Self-priming |

| F | Fluoroplastic |

| 80 | The inlet dia is 80mm |

| 65 | The out let dia is 65mm |

| 160 | Nominal dia of impeller is 160mm |

一、Product Introduction:

Product overview:

THZF fluorine lined self-priming pumpis in accordance with the national standards for the design of new technology products and combining the TIF pump design and manufacturing technology, the pump body is composed of a suction chamber, a liquid storage chamber, scroll, back hole, gas-liquid separation chamber etc. composition. Pump start under the action of centrifugal force, residual liquid suction chamber and into the fluid in the pipeline in the air was stir the mixture of water and air into the impeller, the mixture after the volute into gas-liquid separation chamber, with the slower velocity, resulting in gas water separation, air from the pump out liquid outlet, liquid return pump through the return hole, after several cycles, in liquid pipelines in discharging the air net, pump to form a vacuum degree, achieve self absorption effect, performance reached the international standards, can replace expensive imported chemical pump.

Features:

1.THZF fluorine lined self-priming pump is designed voluntarily by ourselves according to international standards of IS02858/DIN24256. Its technical index and performance has already reached domestic and international advanced level of similar products.

2.The whole pump body be sintered and pressed of cast-iron with fluorine lining (PTFE, FEP, and PEA). The flowing-passed components like pump body, impeller, pump cover are entirely pressed and sintered of fluoroplastic (PTFE, FEP, PFA) covering metal insert.

3. The shaft seal is built-in type single mechanical seal; the optional grinding sealing surface: silicon carbide, cemented carbide, etc; Clients also can choose double mechanical seal or external mechanical seal as required, to make sure satisfy the demand of delivering all kinds of medium and the working life of shaft seal.

4.International standard axial coupling pull back design, no need to dismount pipe, easier maintenance. Horizontal mount, compact structure, low voice, small vibration, small occupation and stable operation.

5.The design of self-priming and gas-liquid mixture has strong function of self-priming, the height can reach 4 meters.

Application:Widely applied to many fields or processes like petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Performance range:Design pressure:1.6Mpa、Flow:2-120m3/h、Head:20-80m、Power:1.1-37kw

Applicable temperature:-30~120℃,can be up to 180℃ if using new type material.

NOTES: No idling running. No delivering medium with particles or crystalline.

二、Structure drawing:

三、Performance Curve:

| Part | Material | Part | Material | Part | Material |

| 1.front cover | HT200/F46 | 8.dynamic ring | SSIC/hard alloy | 15.gland of back bearing | HT200 |

| 2.pump body | HT200/F46 | 9.bracket | HT200 | 16.pump coupling | 45# |

| 3.outlet flange | HT200/F46 | 10.gland of front bearing | HT200 | 17.diaphragm | 304 |

| 4.impeller | Fluoroplastic alloy | 11.front bearing | Gcr15 | 18.electric couplling | 45# |

| 5.pump cover | HT200/F46 | 12.pump shaft | 45#/304/316/316L | 19.shield | 304 |

| 6.static ring | SSIC/hard alloy | 13.bearing box | HT200 | 20.motor | per client request |

| 7.seal gland | 304/316/316L | 14.back bearing | Gcr15 | 21.base plate | HT200 |

四、Performance data sheet:

| model | flow m3/h |

Head m |

effectiveness | NPSH m |

Inlet×Outlet | Self-priming |

Rotating speed | power | weight | |

| % | m | mm | Headm | 时间s | r/min | kw | kg | |||

| TIZF25-25-125 | 1.5 | 22 | 10 | 3 | 25x25 | 1 | 180 | 2900 | 2.2 | 65 |

| 3.6 | 20 | 20 | ||||||||

| 6 | 16 | 30 | ||||||||

| TIZF40-50-125 | 5 | 22 | 35 | 3 | 40x50 | 1 | 180 | 2900 | 3 | 47 |

| 8 | 20 | 42 | ||||||||

| 12 | 17 | 40 | ||||||||

| TIZF40-50-160 | 5 | 32 | 24 | 3.5 | 40x50 | 3 | 150 | 2900 | 4 | 160 |

| 8 | 30 | 48 | ||||||||

| 12 | 28 | 45 | ||||||||

| TIZF50-50-125 | 8 | 22 | 35 | 3 | 50x50 | 1 | 180 | 2900 | 3 | 47 |

| 12 | 20 | 42 | ||||||||

| 15 | 17 | 40 | ||||||||

| TIZF50-50-160 | 8 | 32 | 24 | 3.5 | 50x50 | 3 | 150 | 2900 | 4 | 160 |

| 12 | 30 | 48 | ||||||||

| 15 | 28 | 45 | ||||||||

| TIZF50-32-200 | 8 | 52 | 24 | 3.5 | 50x32 | 3 | 150 | 2900 | 7.5 | 210 |

| 12 | 50 | 35 | ||||||||

| 15 | 43 | 32 | ||||||||

| TIZF50-32-250 | 8 | 82 | 20 | 4 | 50x32 | 3 | 150 | 2900 | 15 | 320 |

| 12 | 80 | 26 | ||||||||

| 25 | 65 | 39 | ||||||||

| TIZF65-50-160 | 15 | 32 | 40 | 4 | 65x50 | 3 | 200 | 2900 | 7.5 | 210 |

| 25 | 30 | 55 | ||||||||

| 35 | 27 | 48 | ||||||||

| TIZF65-50-200 | 15 | 47 | 30 | 4 | 65x50 | 3 | 180 | 2900 | 11 | 300 |

| 25 | 45 | 42 | ||||||||

| 35 | 38 | 44 | ||||||||

| TIZF65-50-250 | 15 | 72 | 30 | 4 | 65x50 | 3 | 180 | 2900 | 18.5 | 440 |

| 25 | 70 | 41 | ||||||||

| 35 | 65 | 42 | ||||||||

| TIZF80-65-160 | 35 | 32 | 54 | 4.5 | 80x50 | 3 | 150 | 2900 | 11 | 284 |

| 50 | 30 | 58 | ||||||||

| 60 | 25 | 48 | ||||||||

| TIZF580-50-200 | 35 | 47 | 45 | 4.5 | 80x50 | 3 | 180 | 2900 | 15 | 330 |

| 50 | 45 | 53 | ||||||||

| 60 | 42 | 46 | ||||||||

| TIZF80-50-250 | 35 | 72 | 45 | 5 | 80x50 | 3 | 180 | 2900 | 30 | 550 |

| 50 | 70 | 50 | ||||||||

| 60 | 65 | 43 | ||||||||

| TIZF100-80-160 | 65 | 32 | 54 | 6 | 100x80 | 3 | 250 | 2900 | 18.5 | 390 |

| 100 | 30 | 60 | ||||||||

| 110 | 26 | 54 | ||||||||

| TIZF100-80-200 | 65 | 46 | 48 | 6 | 100x80 | 3 | 250 | 2900 | 30 | 500 |

| 100 | 45 | 55 | ||||||||

| 110 | 40 | 48 | ||||||||

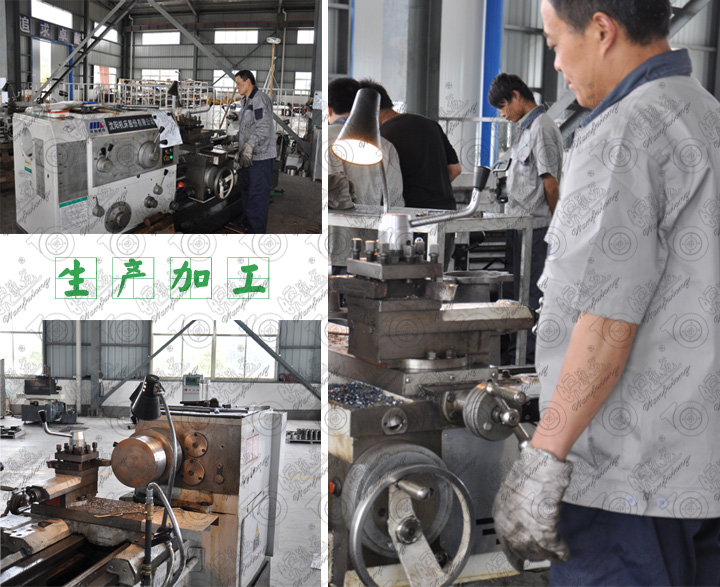

五、Production workshop:

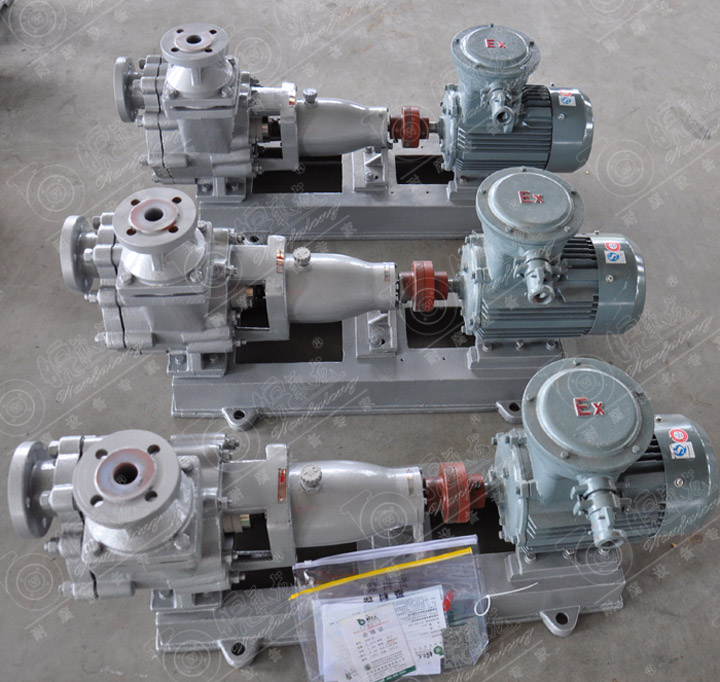

六、Product real: